Inspection and Quality Control Services

At Day Tool & Mfg, our inspection services are a natural extension of our dedication to providing the highest quality precision tooling and dies to customers in advanced manufacturing industries. A part will never be more accurate than the tooling on which it is produced, making the accuracy of dies and fixture critical to producing consistent parts that meet all dimensional tolerances.

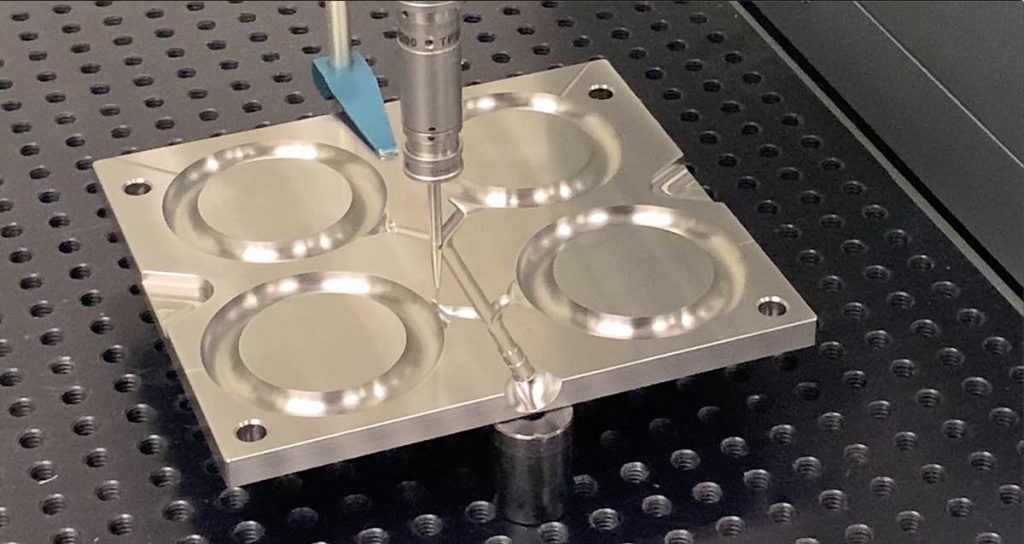

Inspection services include the measurement and evaluation of all dimensional characteristics and their corresponding geometrical tolerancing critical to the performance of the tooling or a component. A manual and CNC equipped CMM on our shop floor are used to verify these dimensions to precision tolerances. Inspections may be performed as part of a first article inspection in accordance with SAE AS9102 procedures, or as otherwise designated by customer specifications.

Additional available services include comprehensive product development using CAD design programs, as well as complete fabrication, machining, assembly, and testing of dies, fixtures, and other tooling. Our quality management system has continuously been AS9100, Rev D and ISO 9001:2015 certified, documenting our commitment to providing premium quality service to the aerospace, automotive, biotechnology, and medical industries.

Turnaround times are evaluated on a job-by-job basis, but average approximately two weeks. For additional information about all of our inspection capabilities, see the table below, or contact us directly.

Inspection and Quality Control Equipment & Capabilities

| General Capabilities | Consulting Engineering |

| Inspection Characteristics & Properties | Dimensional Concentricity Contour Roundness Straightness |

| Inspection Methods | Coordinate Measuring Machines (CMM) CMMs are a mechanical system designed to move a measuring probe to determine coordinates of points on the surface of a work piece. First Article Inspection (FAI) Defines the activities for first article inspection that is compliant with SAE AS9102A. Prime contractor requirements of the AS9102 FAI procedure to Suppliers that have design authority |

| Equipment | CNC Coordinate Measurement Machine Shop Floor Manual CMM Visual Comparator |

| Value Added Services | Assembly CAD CAM Fabrication Machining Product Design Assistance Product Development Testing |

| Typical Lead Time | 2 weeks; quoted on a job-by-job basis |

Additional Information

| Industry Focus | Aerospace Appliance Automotive Biotech Electronics Machining Medical Military Packaging Petrochemical Pharmaceutical Semiconductor |

| Intended Application | Precision Tooling Stamping Dies Special Machines Machined Parts |

| Industry Standards | AS 9100, Rev. D Certified (Aerospace Industry Standard) ISO 9001:2015 Certified (International Organication for Standardization) |

| File Formats | AutoCAD DXF DP Technology Esprit GibbsCam GIF IGES JPG/JPEG PC-DMIS CAD SolidWorks STEP |